|

|

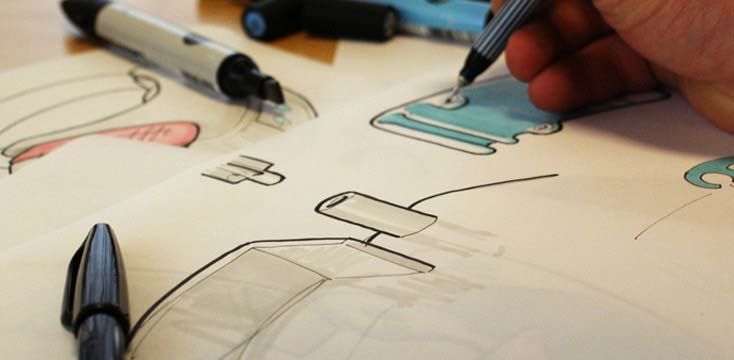

our product design process |

|

Project Briefing & Product SpecificationProjects generally start with an initial discussion over the phone. This is usually followed by a meeting to discuss your requirements and details of the proposed product, including: its specifications, market, design criteria, timescales, etc. Following this we would produce a detailed project proposal, usually broken down into several stages, which outlines the process we would adopt, the deliverables, the cost and the timescale for each stage of work. |

|

Concept GenerationBased on your design brief we would generate a range of initial design concepts for the product. These initial ideas would most likely be wide ranging in their scope and consider more fundamental issues relating to the product, such as: market forces, usability, aesthetics, ergonomics, underlying product architecture, materials & finishes, technical feasibility and mechanical functionality. We would synthesize and evaluate these initial ideas together with you, to quickly focus in on a preferred concept option. This process would allow you to identify and visualize the most suitable product concept and to better understand potential costs, risks and feasibility before proceeding with the main stage of product development.

For more information and examples please see our concept design and ideation page |

|

Design DevelopmentThis is the main part of the product development process and often takes the longest time. In this phase, we would take the product concept and produce a 3D CAD model of the component parts and assembly using SolidWorks. We would confirm any assumptions made at the concept stage and validate the design functionality and materials through a rigorous testing process. We would confirm the ergonomic and usability aspects, specify the colours, materials & finishes to be used, focus on design for manufacture & assembly and discuss the proposed design with prospective manufacturers to ensure that it is optimized for production. For more complex projects the development can sometimes be broken down into several stages closely coupled with rapid prototyping activities.

For more information and examples please see our design development page |

|

Rapid PrototypingAt Brightworks we see prototyping as an essential part of the product development process, as it provides a physical embodiment of the product (or a detailed part of the product) for testing and evaluating before committing to production tooling. Interim prototypes or test rigs may be produced, to prove a particular detail during the development process, and a number of working whole product prototypes are usually produced at the end of the product development phase. There are many different rapid prototyping processes available and several levels of realism that can be achieved depending on requirements. Prototypes may be used for technical evaluation, user trials or sales & marketing purposes. Generally prototypes that mimic the final product entirely in terms of material, finish, feel, and functionality are more expensive.

For more information and examples please see our prototyping page |

|

Production Specification and Manufacturing AssistanceA production specification drawing is produced for each component part of the product and 3D CAD data is carefully checked before it is issued for production tool manufacture. Brightworks would liaise with your manufacturing partners during tool manufacture and check that first off parts are to specification and within tolerance. We have extensive experience in designing for manufacture, with an in-depth knowledge of most production processes such as injection moulding.

For more information and examples please see our productionisation page

Back to top |

|